|  |  |  |  |  |

|---|---|---|---|---|---|

|  |  |  |  |  |

|  |  |  |  |

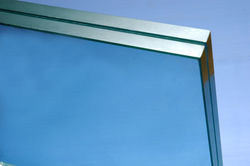

Tempred and laminated glass

The tempered glass is produced by thermal treatment of ordinary glass. The glass is cut to the required size and shape. All machining, such as polishing edges or drilling holes, is performed before hardening. The glass is heated above the 600 ° C hardening point. The glass is then quickly cooled with air.

The tempered glass has a strength of about six times that of ordinary glass. The tempered glass is typically used in frameless elements (for example, as non-framed doors) and for structural purposes. The tempered glass is less risky than ordinary because of its higher strength and because it breaks into small rounded pieces less likely to cause injuries.

The laminated glass (triplex) consists of two or more glasses glued to a flexible transparent film which does not disturb the optical properties of the glass. When broken, laminated glass retains its geometric integrity, making it safe. Depending on the needs, different types of glass can be laminated with different types of adhesive material. Bestimex Ltd. and our partners, we offer complete design and manufacture of glass objects, such as shower cabinets, showcases, glass doors, glass roofs, etc. We offer full color and durable printing on the glass, resistant to atmospheric conditions and abrasive effects.